WORKING WITH GAFFER DAVID SMITH TO CREATE A LARGE SCALE WEATHERPROOF SOLUTION ON NEW MARVEL SERIES

During planning and preparation for an all new Marvel character series, Gaffer David Smith approached the MBSi team with a specific equipment request to help him achieve his creative goals on the production.

In order to deliver sufficient levels of illumination, the substantial exterior sets at Pinewood Studios require space lighting on a grand scale.

MBSi are no strangers to this kind of custom build, with Pinewood MBS Lighting regularly supplying large quantities of fixtures such as Space Force and SkyPanels to meet such requirements.

The ‘regular’ approach to this challenge would be to construct a 40 x 40ft crane mounted scaffolding grid, from which the crew are able to hang suitable fixtures. In such circumstances, before being hoisted into place, a makeshift ‘roof’ is then added to the soft-box structure for protection against the elements.

However, this type of structural installation can be time consuming and can suffer in certain conditions. In particular, wet weather can prove problematic whilst wind speeds in excess of 9mph can render the structure dangerous to work with.

For this new Marvel production, where the requirement was for sets to remain rigged for extended periods of time, it became clear that something a little more robust would be needed.

Having studied the challenge from all angles, David Smith approached the MBSi Technical Team to help create an effective, practical solution.

”“The MBSi Technical Team allowed me the time and scope to properly analyse the challenge and to devise a really effective solution that could potentially go beyond the immediate requirement”

David Smith

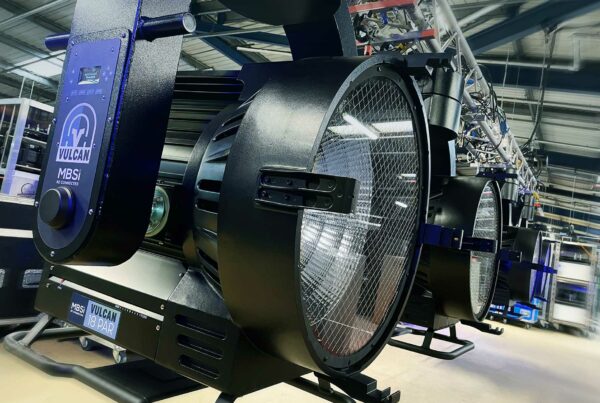

The Solution

Working closely with Gaffer David Smith to ensure the solution would be absolutely fit for purpose, the MBSi team tested various light sources to ascertain the best way in which to combine maximum output and safe operation with protection against the harshest conditions.

Speaking about the project, David Smith said “The Technical Team at MBSi allowed me all the time I needed to properly analyse the challenge and arrive at an effective solution that could potentially go beyond the immediate requirement. Together, we devised a brief to deliver a quality, affordable product, all the while taking care not to over-engineer the end result.”

In keeping with their ongoing commitment to using low energy solutions, both the Gaffer and MBSi were keen to identify an LED based solution. For practical purposes, the product also needed to be lightweight, tough, highly controllable and simple to operate.

David continues “Involvement in the technical aspects of a product is both an important part of my role and something I enjoy. On this particular project, MBSi consulted with me throughout every stage of the development process. This can be invaluable, both in helping build a thourough understanding of a product and realising it’s full creative potential”.

”“AquaBat is both effective and an incredibly robust solution - a perfect solution for the grand outdoor sets we are creating.

David Smith

The functionality of the system far exceeds our initial brief. MBSi have created an incredibly versatile, weatherproof light source capable of delivering accross a broad variety of applications”.

MBSE Technical Director Steve Howard comments “Having decided on a suitable LED configuration we set about testing various ways in which to safely house our concept. We had been working with a selection of lightweight aluminium extrusions which would also prove to be an ideal platform on which to mount the LEDs”.

The chosen extrusion featured a channel, deep enough to house the LEDs. The challenge now was to secure the LEDs whilst effectively dissipating the generated heat and ensuring maximum protection against the elements.

Having tested various options, the team devised an innovative procedure that completely encased the LEDs and all wiring, whilst also allowing heat from the LEDs to easily flow directly away from the light source.

The result of this reasearch and development is AquaBat, a brand new, fully submersible (IP68 rated), modular LED system that is both powerful and environmentally considerate.

Aqua Bat is a fully dimmable, solid state, bi-colour solution that perfectly blends simple, effective operation with safe, versatile performance.

Steve continues “We rigorously test every product we design to ensure completely safe operation at all times. With AquaBat, we were particularly thorough, not only to make sure the fixture is an effective, reliable light source but that it remains totally safe in all conditions”.

Exclusive to MBSi, AquaBat is available as 4ft and 8ft lengths which can be easily rigged to create soft boxes with an almost infinite choice size and shape. Dependable, lightweight yet tough, AquaBat can withstand harsh exterior conditions for extended periods, saving crews valuable rigging time whilst also helping build a safer working environment. A perfect match for the grand exteriors created for this project.

Steve concludes “We pride ourselves on forging strong working relationships with Production Crews. It’s these relationships that allow Gaffers to comfortably approach us with technical challenges or to develop ideas straight from the set that go beyond the realms of what is available at the time. It’s been an absolute pleasure to work with David on this project”.